- © 2023 Neil Austin Contact Me 0

3D printing, also known as additive manufacturing, is a process of creating physical objects from a digital design by layering materials in a sequential manner. This process involves the use of specialised 3D printers that can create three-dimensional objects using a variety of materials, including plastics, metals, ceramics, and even food.

The process of 3D printing typically involves the following steps:

Design: A digital model of the object is created using computer-aided design (CAD) software or by using a 3D scanner to create a digital model of an existing object.

Slicing: The digital model is sliced into multiple thin layers, typically ranging from 0.05 to 0.3 millimetres thick, depending on the printer and the material being used.

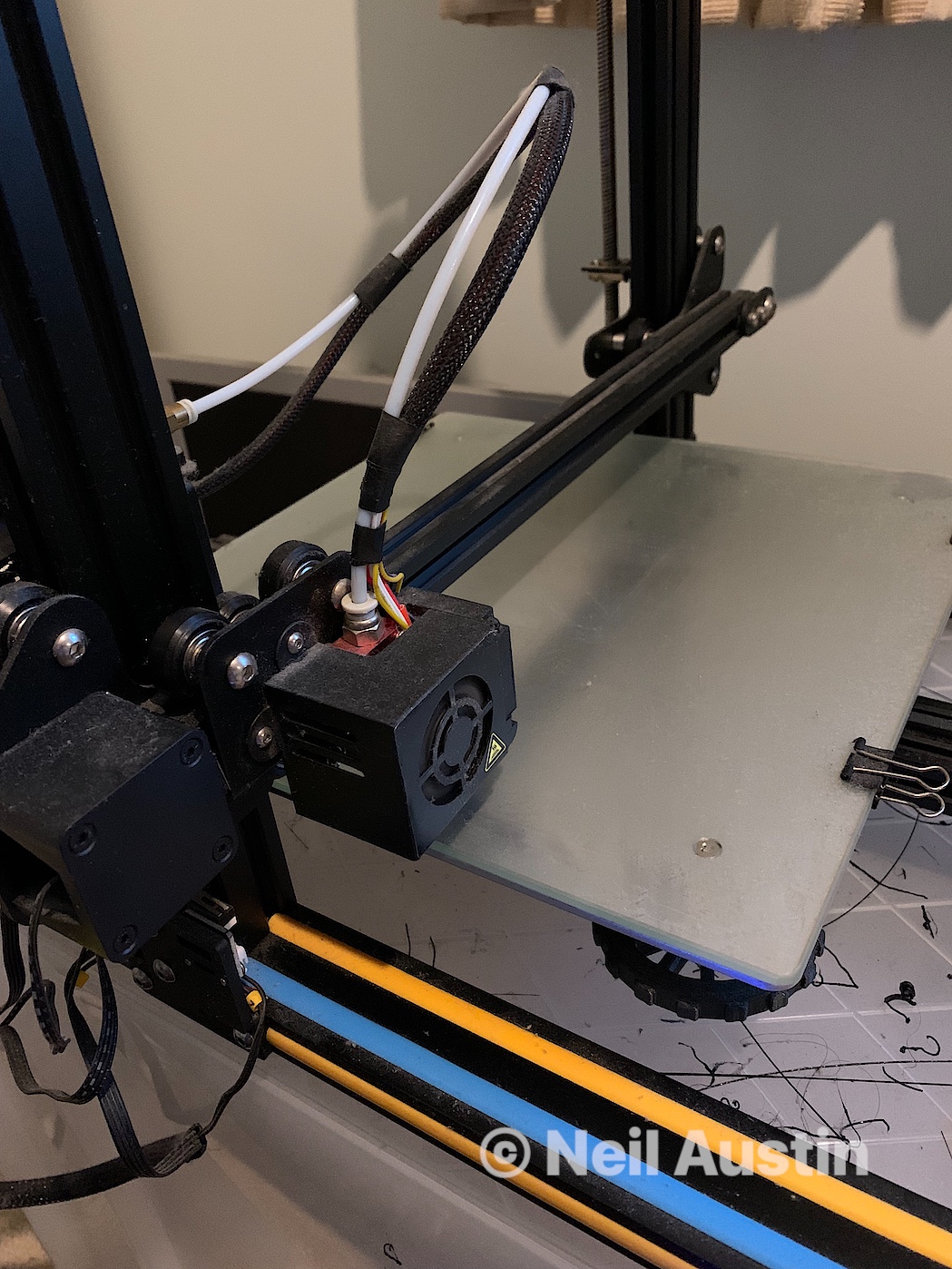

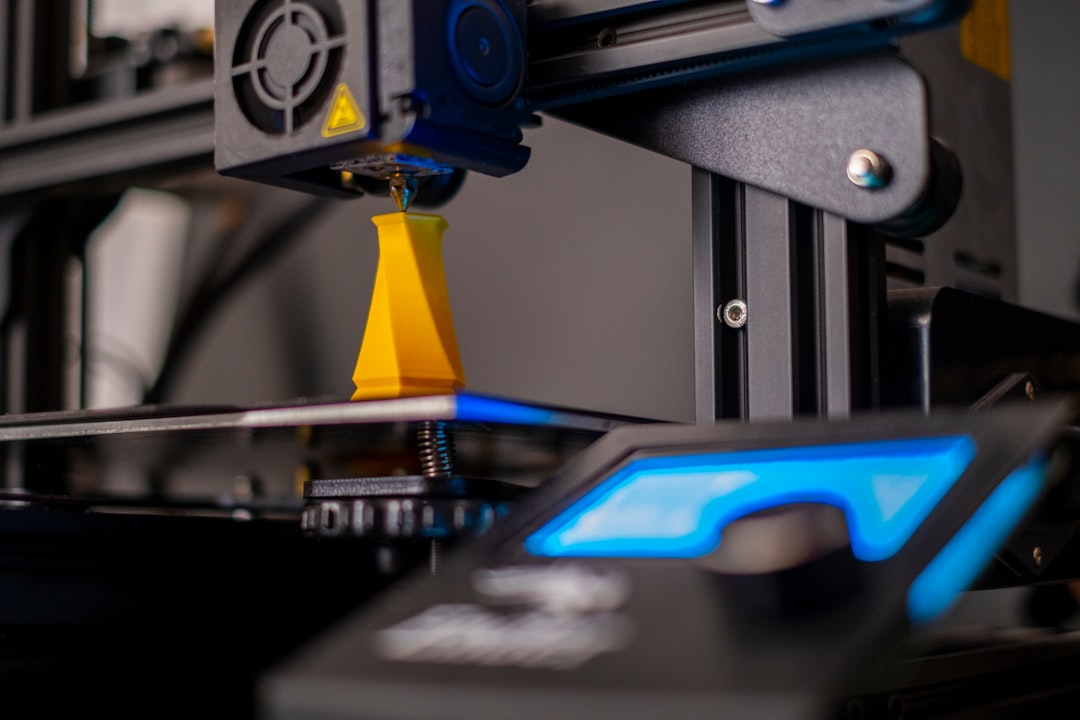

Printing: The 3D printer creates the object by layering the material one thin layer at a time, typically by extruding molten plastic or other materials through a heated nozzle or by using a laser to fuse powdered materials.

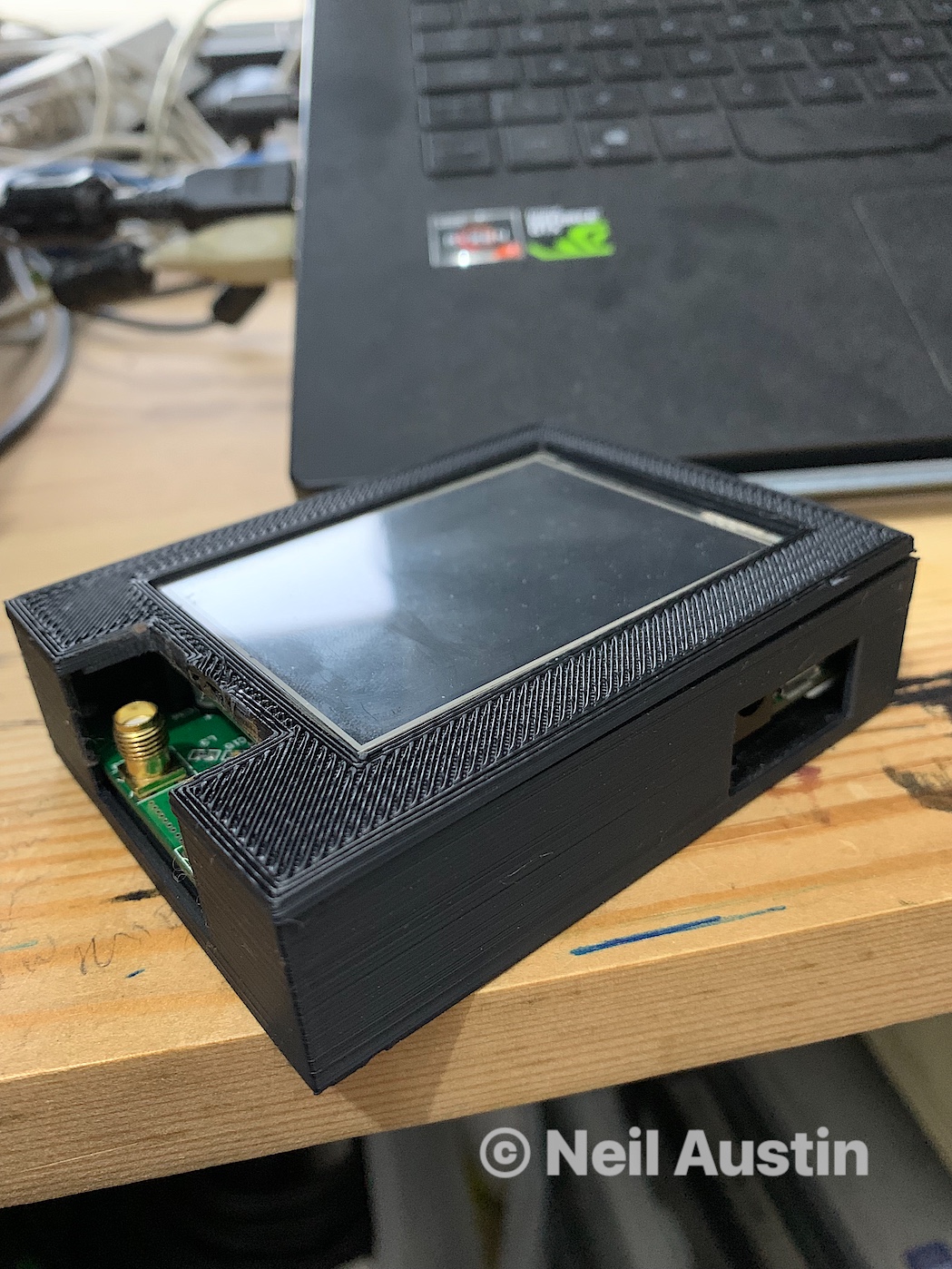

Finishing: Once the object is printed, it may require additional finishing processes such as sanding, polishing, or painting to achieve the desired appearance and functionality.

There are a variety of different 3D printing technologies available, each with their own strengths and limitations. Some of the most common types of 3D printing technologies include:

Fused Deposition Modelling (FDM): FDM is one of the most widely used 3D printing technologies, which involves extruding melted thermoplastic material through a nozzle to create the object layer by layer.

Stereolithography (SLA): SLA uses a laser to cure a liquid resin, creating solid layers that build up to form the object.

Selective Laser Sintering (SLS): SLS uses a laser to sinter or fuse powdered materials together to create solid layers.

Digital Light Processing (DLP): DLP uses a projector to cure liquid resin layer by layer, creating the object.

3D printing has revolutionised the manufacturing industry, making it possible to create highly customised and complex objects quickly and cost-effectively. It has also enabled the production of objects that were previously difficult or impossible to create using traditional manufacturing methods. 3D printing has applications in a wide range of industries, including aerospace, automotive, healthcare, and consumer goods, and it is likely to continue to play a significant role in the future of manufacturing and product development.